MACHINERY MANUFACTURING

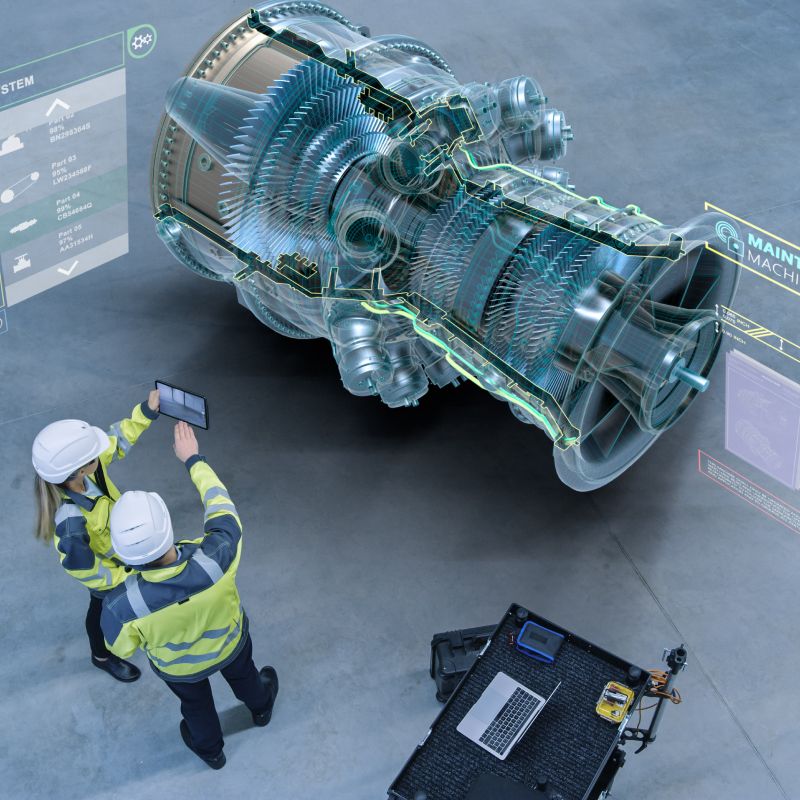

Boosting Industrial Efficiency with IntegratedXR and AI

The manufacturing sector plays a fundamental role in driving economic growth and innovation. To remain competitive, industrial companies are constantly seeking ways to enhance efficiency, optimize workflows, and reduce operational costs.

In this pursuit, technology becomes a strategic asset—and IntegratedXR solutions, powered by AI and 3D visualization, are transforming how manufacturing processes are designed, executed, and maintained.

At Vection Technologies, we provide mission-critical tools tailored to the industrial world, including: 🔹 Augmented Reality (AR) for step-by-step guidance and hands-free operations 🔹 Virtual Reality (VR) for immersive training and simulation 🔹 3D modeling and real-time rendering for rapid prototyping and design validation 🔹 Remote assistance and digital procedures for efficient maintenance and reduced downtime 🔹 AI-powered platforms for predictive support, data extraction, and process automation

From the factory floor to the control room, our IntegratedXR ecosystem empowers manufacturers to operate smarter, faster, and more safely—unlocking new levels of productivity and resilience.

What is Extended Reality (XR) Technology?

XR is an umbrella term used to describe immersive technologies and interactive experiences, including Augmented Reality (AR), Mixed Reality (MR), and Virtual Reality (VR). These immersive technologies show the reality we experience by combining the real and virtual worlds.

Uses Cases for XR Technology

Extended Reality (XR) is a critical technology to enhance production, reduce cost and drive productivity. Below you can find some critical use cases for XR technologies in the machinery manufacturing industry.

Minimizing Downtime in Global Manufacturing

In the machinery and equipment industry, even short downtimes can disrupt global production chains.

With AI-powered immersive solutions, Vection Technologies enables technicians to receive real-time support through AR overlays, smart suggestions, and remote expert guidance—directly in their field of view.

🔹 Visualize CAD data in AR 🔹 Get AI-driven diagnostics and next-best actions 🔹 Automate reporting and boost operational efficiency

Faster interventions, smarter decisions, and global support—powered by AI and immersive reality.

Accelerating Product Development

AI and immersive reality are transforming product development in manufacturing—enabling teams to collaborate in real time, validate designs earlier, and reduce prototyping cycles.

With IntegratedXR solutions from Vection Technologies, companies can visualize and test products in virtual environments, while AI accelerates decision-making through real-time data analysis, design suggestions, and automation.

This powerful combination helps bring better products to market, faster and smarter—reducing time-to-market and driving innovation across the entire development lifecycle.

Smarter Industrial Training

Training in manufacturing no longer requires travel or generic content. With immersive reality and AI-powered platforms, companies can deliver interactive, hands-on learning experiences anytime, anywhere.

Through Virtual Reality (VR) and Augmented Reality (AR), employees can simulate real operations, while AI personalizes training paths, monitors performance, and provides real-time guidance—reducing costs and boosting knowledge retention.

Vection Technologies enables scalable, effective training that keeps industrial teams skilled, safe, and productive.

AI and Immersive Reality for Smarter Workforce Support

In manufacturing, immersive reality and AI offer intuitive, real-time guidance to help workers solve complex tasks faster and more accurately.

New technicians can access interactive manuals and live remote support, while AI-driven systems adapt instructions based on user needs—boosting learning, reducing errors, and accelerating performance.

With Vection Technologies, teams become more autonomous, skilled, and aligned—driving measurable gains in productivity.

Enhancing Collaboration with Immersive Reality and AI

Immersive technologies combined with AI enable teams to collaborate in real time within shared virtual environments—no matter where they are.

Through VR and AR, departments can co-design, review, and solve challenges together, while AI supports decision-making with contextual data and smart suggestions.

With Vection Technologies, collaboration becomes faster, smarter, and truly borderless.

Driving Manufacturing Sales

AI and immersive reality are transforming how manufacturing companies sell—enhancing product presentations, streamlining remote sales, and boosting lead conversion.

With AR/VR experiences powered by AI, teams can showcase complex products interactively, personalize content, and support omnichannel strategies with data-driven insights.

Vection Technologies helps turn every sales interaction into a high-impact, immersive experience—anywhere in the world.

Takeaway

When adopting new technological solutions, businesses must ensure they have in place adequate knowledge, training and change management processes.

That is why, global clients are choosing Vection Technologies to integrate XR within their manufacturing processes. Vection Technologies has developed a range of solutions and critical know-how to support global businesses in their XR digital transformation strategies.