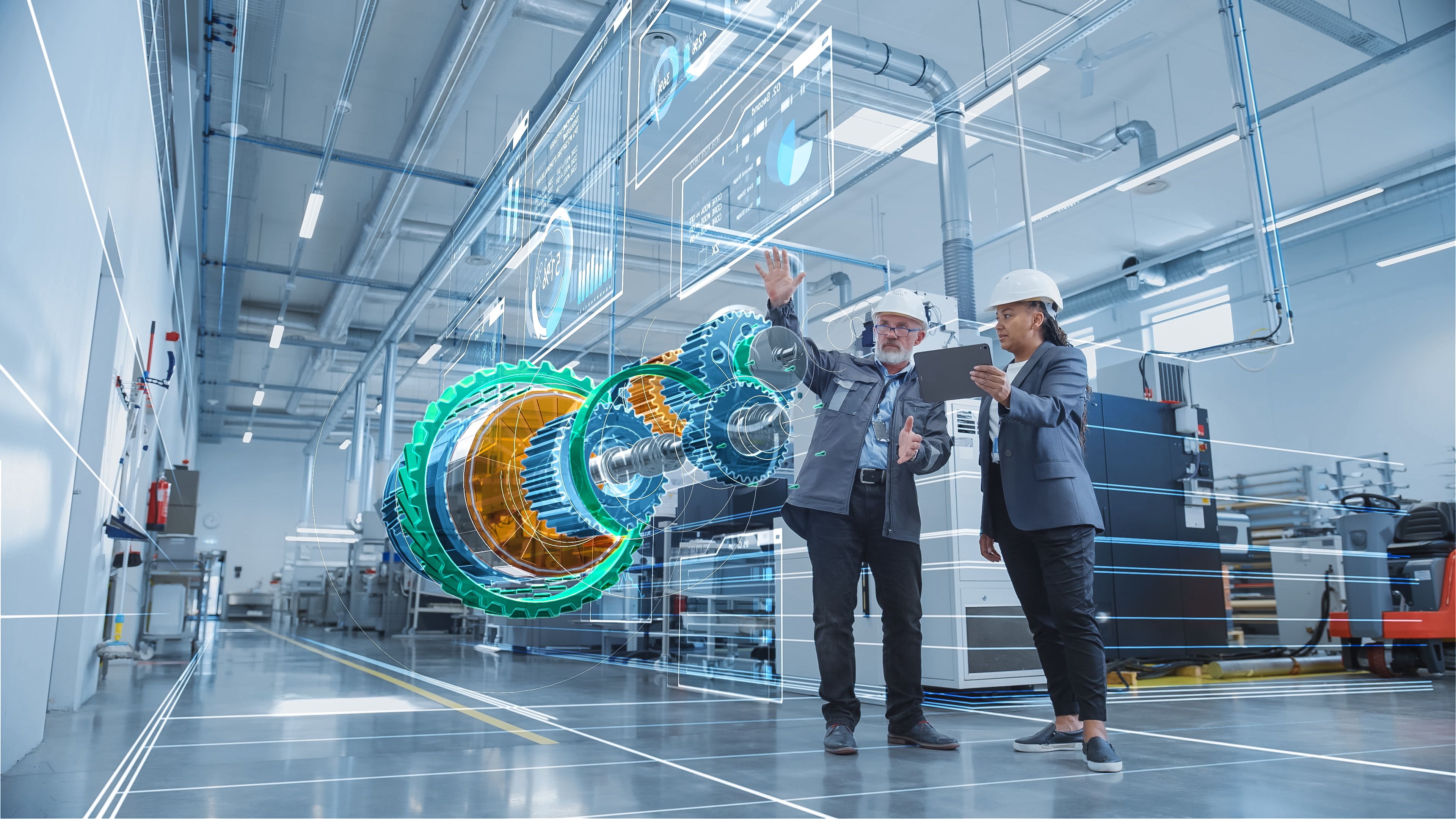

Concurrent engineering allows designers, manufacturers, architects, and other specialists to create products synchronously. This is considered an efficient approach to engineering since it helps reduce costs and improve quality. Although concurrent engineering is quite effective, it can be complex to implement it. This explains why you need cost-effective solutions and time efficiency during concurrent engineering projects. One of these solutions is undoubtedly virtual reality (VR). VR not only optimizes concurrent engineering processes but also adds other advantages to them, such as enhanced collaboration and faster iterations with fewer errors. In this blog post, we’ll uncover the benefits of VR in concurrent engineering. We'll also explain its applications to virtual prototyping, assembly line phases, and product presentation meetings.

Concurrent Engineering Phases

Concurrent engineering unfolds product development processes. These processes usually involve relevant stakeholders, who collaborate to research, design, and manufacture products for the market.

Moreover, concurrent engineering can be represented in the following phases:

• Market investigation

• Product design

• Conceptual design, evaluation and development

• Detail design

Concurrent engineering phases are reflected in many initiatives, including virtual prototyping, assembly line process, and virtual product presentation meetings. We’ll explore each of them.

Concurrent Engineering and Virtual Prototyping

Virtual prototyping is key in concurrent engineering. It allows you to create digital models and product simulations. Through VR, designers and developers construct virtual prototypes to simulate real-world physical behaviors toward a specific product, including motion, lightning, and collision detection.

Virtual prototyping has been increasing due to its benefits for companies, like diminished time to market and quality, as stated in a report by Grand Review Research. This report reveals that the global market size for virtual prototypes was USD 210.4 million in 2017, and it’s expected to grow at a CAGR of 19.4% between 2018 and 2025.

Let's explore the benefits and current applications of virtual prototyping.

Uncover the Benefits of Virtual Prototyping

When it comes to creating realistic product models, virtual prototyping is a powerful tool, and you should learn why.

Here are four benefits of introducing virtual prototyping in your operations:

• Cost reduction: With virtual prototyping, you can save costs associated with traditional physical prototypes in concurrent engineering projects.

• Improved collaboration: Enhanced collaboration and communication are gold for designers and developers because it makes product creation more efficient.

• Faster iterations: By using virtual prototyping, you’ll be able to streamline iterations, minimizing the time required to have a final product in concurrent engineering processes.

• Fewer errors: Decreasing errors with virtual prototyping will enhance the quality of your products. Thanks to virtual prototyping, you can detect any potential issues in the process, reducing repetitions, costs, and conflicts with clients. It’s a win!

Virtual Prototyping: Success Cases

Big industry players in aerospace and automotive have quickly adopted virtual prototyping and witnessed exceptional outcomes in concurrent engineering projects.

Let's take a closer look:

• Ford: Ford designers have been using VR to prototype cars and determine if they work well with virtual drivers. When cars’ prototypes are evaluated in a virtual environment, and errors are identified, they can reduce iterations, costs, and time from weeks to a few hours.

• NASA: Specialists have been utilizing VR technologies to develop assembling and maintenance operations in the International Space Station. As a part of the Pilot investigation, VR has been utilized to test the remote operations of robots and space vehicles.

• Airbus: In 2017, this corporation used VR to showcase the amenities and luxurious features of the A3309neo and 350 XWB cabins.

Concurrent Engineering and Assembly Line Processes

Did you know that virtual reality is also revolutionizing assembly line processes? If you’re interested in learning more about how this enables workers to visualize and interact with final products in virtual settings, keep reading.

Business owners, designers, manufacturers, and engineers alike can feel intimidated by the assembly line’s complexity, but there’s nothing to be worried about. Here’s how VR is benefiting operations associated with assembly line phases quickly.

Benefits of VR During the Assembly Line Processes

VR benefits all aspects of the assembly line phases. To give you an example, VR has been proven effective when it comes to optimizing line assembly and testing potential changes in the layout without having to halt production.

Do you want to discover other advantages of VR in the assembly line phase? Here are more!

• Reduced downtime: VR can help decrease downtime when lines need to shut down for retooling or configuring new concurrent engineering processes.

• Enhanced quality control: VR is an alternative when it comes to quality control in assembly lines. If you use virtual reality, you can create accurate simulations of products. Then, manufacturers can use these simulations as a resource to identify defects or flaws before the assembly line is in place. Can you imagine how beneficial implementing VR in your quality control procedures would be?

• Effective onboarding and training: Thanks to virtual reality technologies, your new employees can get training in assembly line simulated settings. This will help them learn assembly procedures before stepping into the production facility. Are you wondering how to train your employees safely? Try EnWorks today!

Concurrent Engineering and Virtual Product Presentations

Have you ever been in a business meeting where the product presentation failed to engage decision-makers, and everyone seemed bored? You can avoid this situation by forging interesting presentations and collaborative meetings with VR technologies.

With VR, you can bring people from different countries or cities together to discuss details regarding an innovative product. This will lead you to speed up your clients’ decision-making processes and increase your product’s sales in concurrent engineering projects.

In a business virtual meeting, the possibilities are endless. You can use virtual objects, simulations, and other tools to foster conversations and keep your attendees on the same channel.

Additionally, you can motivate your attendees and prospects to explore your own professional metaverse and see firsthand how your product was designed, assessed, and manufactured in concurrent engineering projects.

Because you don’t have to invest in additional resources for your attendees’ accommodation or think about travel expenses, solutions like 3DFrame will allow you to able to scale down costs while improving sales operations in concurrent engineering initiatives.

You’ll be ready to get the most out of the business metaverse and concurrent engineering with Vection Technologies! If you want to become a pro at creating engaging product presentations with VR, read our blog post here.

Takeaway

VR is a total-game changer for concurrent engineering, just like it’s shaking up other industries too. The benefits and uses of VR are numerous.

For example, VR allows designers, engineers, manufacturers, and specialists to reduce time and resources, decrease iterations, create high-quality products with fewer errors, enhance collaborative efforts, showcase product design to sales, and improve approaches to concurrent engineering projects.

If you’re interested in adopting a VR strategy for your engineering projects, contact Vection Technologies today.