How VR and AR Technologies Foster Collaboration in the Machinery Manufacturing Industry

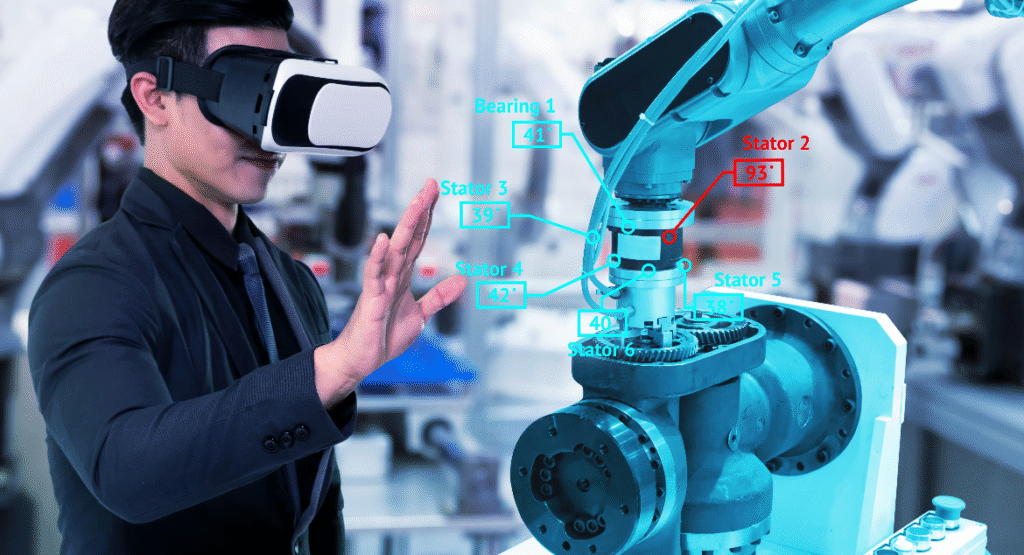

VR and AR technologies are some of the most advanced tools for fostering collaboration in the machinery manufacturing industry.

Virtual and augmented realities allow teams to work together remotely, from different offices or even different countries, by providing them with an immersive experience that makes them feel as if they’re all working together in one space. This allows teams to brainstorm ideas, build prototypes, or test products without needing to be physically present with each other.

In addition, these technologies can guide customers through complex systems or processes without having to be there physically. This eliminates the need for tedious explanations over emails or phone calls and allows customers to understand your product or service better quickly and easily.

For example, Mindesk can help you foster collaborations in machine manufacturing companies regarding design. Also, Enworks can foster collaborations in remote training, which allow you to save expenses on on-site visits or meetings.

5 Benefits of Collaboration in the Machinery Manufacturing Industry

Fostering collaboration in machinery manufacturing companies has many benefits. Here are five:

Improved Communication

By fostering collaboration between employees of different departments, machinery manufacturing companies can improve communication and ensure that all parties clearly understand their roles and responsibilities.

This helps to avoid any confusion or misunderstandings that can lead to costly delays or errors in the production process. Additionally, it allows for a smoother flow of information between departments, enhancing overall efficiency.

Increased Efficiency

As mentioned above, team collaboration leads to more efficient processes due to improved communication.

With open lines of communication, ideas can be shared quickly and efficiently, resulting in better decision-making and fewer mistakes throughout the production line. Collaboration maintains production time frames while reducing costs associated with rework or wasted resources.

Faster Problem Solving

When faced with challenging problems, teams can come together to brainstorm innovative solutions more quickly than if each team was working independently.

Collaboration also opens the door for creative ideas from unexpected sources, which may not have been considered otherwise. This adds another layer of potential problem-solving strategies that could cause faster fixes for troublesome issues or entirely new innovations altogether!

Cost Savings

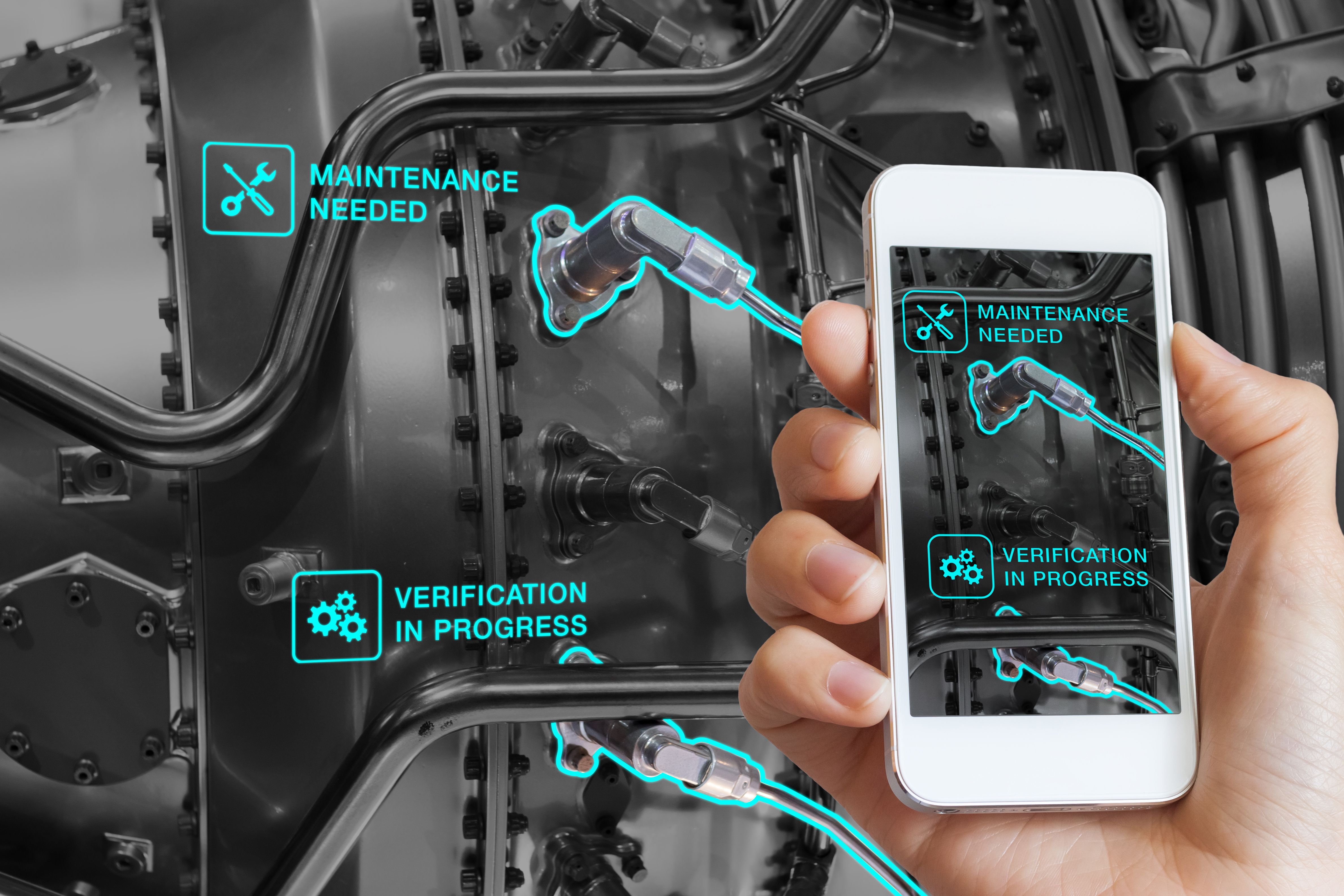

By using VR and AR technologies, machinery manufacturing companies can save money for prototyping and testing products before they hit the market.

This cuts down on the required materials upfront and eliminates any additional labor costs associated with redesigning products after they’ve been released—both of which would have increased expenses without collaboration among teams.

Enhanced Morale

Working together towards common goals creates a sense of unity among employees that can positively affect team morale and inspire higher levels of productivity when individuals feel they are part of something bigger than themselves!

Allowing employees to contribute ideas collaboratively rather than individually this fosters an environment where everyone’s opinion is valued–leading to greater job satisfaction and overall employee engagement within the company at large.

How to Get Started with VR and AR for Collaboration in Machine Manufacturing Companies?

Companies can increase productivity and foster a more collaborative environment using immersive, extended reality technologies.

Read this step-by-step mini-guide to introduce VR and AR technologies to foster collaborations in machine manufacturing companies.

Step 1: Identify Your Goals

Before diving into implementing VR and AR technologies, you must think about what you want to achieve.

Do you want to improve collaboration between remote teams? Or perhaps you want your employees to be able to visit customers virtually or work on projects together?

Once you know the goals of your project, then you can move on to the next step.

Step 2: Choose the Right Technology

There are many options available when it comes to choosing the right technology for VR and AR applications. Before making a decision, you need to consider factors such as cost, user experience, scalability, and compatibility with existing hardware and software.

For example, if you’re looking for an affordable solution that is easy to use, then Vection Technologies’ solutions are a good option. You can get the most of these solutions to improve decision-making, collaboration, and productivity solutions.

Step 3: Create a Plan

Once you have identified your goals and chosen the right technology for your project, it’s time to create a plan. This should include details such as timeline, budgeting requirements, employee training needs, hardware/software requirements, etc.

It’s also important to consider any potential risks associated with using these technologies and how they will be addressed. A logical plan will help ensure your project runs smoothly from start to finish.

Conclusion

In today’s business world, fostering a collaborative environment within your company is more important than ever. By using VR and AR technologies, machinery manufacturing companies can save money for prototyping and testing products before they hit the market.

This cuts down on the required materials upfront and eliminates any additional labor costs associated with redesigning products after they’ve been released-both, which would have increased expenses without collaboration among teams.

Likewise, allowing employees to contribute ideas collaboratively rather than individually fosters an environment where everyone’s opinion is valued-leading to greater job satisfaction and overall employee engagement within the company at large!

If you’re looking for ways to improve productivity and collaboration in your machine manufacturing company, VR and AR may be the answer you’ve been searching for! Contact us to learn how these technologies can benefit your business chain value.