How VR is Making Manufacturing Industries More Efficient: 9 Applications

Virtual reality is quickly making its way into a variety of industries, and manufacturing is no exception. By allowing workers to virtually experience the manufacturing process, it is helping to increase efficiency and reduce errors.

Perhaps most importantly, virtual reality is providing a new level of training for workers in the manufacturing industry. By exposing them to potential hazards and errors, VR apps ensure that workers are better prepared for the real-life challenges of the job.

In the future, virtual reality is likely to play an even more important role in the manufacturing industry, as companies continue to find new ways to use this cutting-edge technology.

In this blog post, we show you nine applications of this immersive technology in the manufacturing industry.

Factory Floor Planning

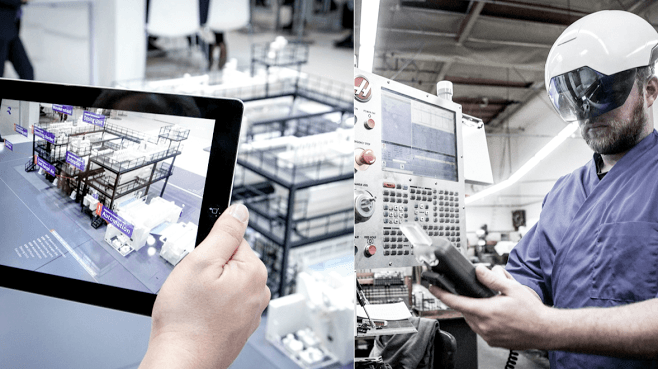

VR is becoming increasingly popular in factory floor planning because it allows manufacturers to see how a proposed layout will look and function before any changes are made to the physical space.

This can help to identify potential issues with the layout, such as bottlenecks or areas where traffic will be congested.

Moreover, virtual reality can also simulate different manufacturing processes, which can help optimize the flow of materials and workers on the factory floor.

In addition, virtual reality can be used to train workers on new equipment or procedures and ensure that factory floors are safe, efficient, and capable of meeting the demands of specific products.

Design and Engineering

VR has increasingly been used in design and engineering because it allows for creating accurate models of products and manufacturing processes. Also, virtual reality enables designers to create products that are more likely to succeed in the market.

For instance, virtual reality has been extensively applied in the automotive industry because it allows engineers to create and test virtual models of vehicles before they are built, which saves time and money. Likewise, VR can also be used to check for faults in components or to assess the condition of an assembly line.

Finally, virtual reality provides a safe environment for engineers to work in and can help them improve the quality of their work. This explains why this technology is an essential tool for design and engineering, and its use is only likely to increase in the future.

Learn more about real-time design review in VR and the Unreal Engine.

Safety Training

VR is quickly becoming an essential tool for safety training in a variety of industries. For instance, virtual reality simulations can provide a realistic and immersive experience that allows trainees to practice safety procedures in a controlled environment.

In addition, VR simulations can also be customized to specific work environments, making them an ideal tool for companies that have complex or dangerous workflows.

Consequently, virtual reality has already been used successfully in a variety of safety training scenarios, including firefighting, hazardous materials handling, and manufacturing.

Learn more about how Vection Technologies is revolutionizing training.

Employee Instruction and Training

Virtual reality is often used in employee instruction and training for several reasons. First, it can provide a realistic and immersive experience that is difficult to replicate in other ways. This can be particularly important in manufacturing or other settings where there is potential for danger.

Credits: Stephan Sorkin

Second, virtual reality can also create simulations of work environments or tasks that employees will need to perform. This allows employees to get a feel for the work they will do without actually having to do it, which can be a safer and more efficient way to train employees.

Third, virtual reality has been applied to employees’ skills and progress assessments. By tracking their performance in VR simulations, employers can get a better idea of which employees are performing well and which ones need more training.

Learn more about how Vection Technologies 3D interactive manuals.

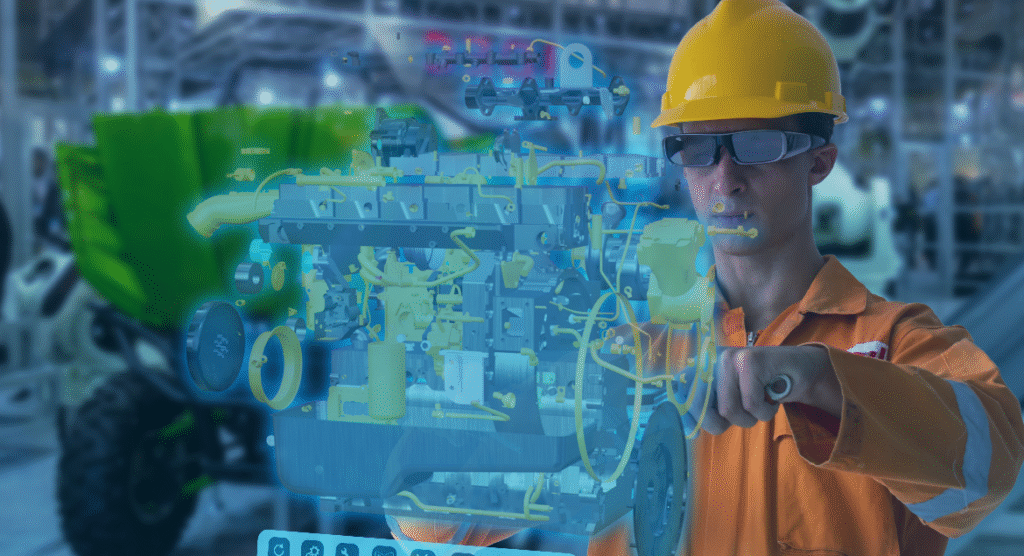

Inspection and Maintenance

Virtual reality has been utilized in inspection and maintenance for some time now. By placing headsets on, users are transported into a 3D digital replica of the manufacturing process or system being inspected. This allows for a more immersive and thorough inspection, as VR lets users walk around, zoom in, and explore different areas in detail.

Additionally, virtual reality can be used to train new employees on how to properly inspect and maintain a system, as it allows them to see and interact with the digital replica in a safe and controlled environment. For instance, VR can create simulations of different scenarios, such as equipment failure, so that employees can be prepared for potential dangers.

Trade Events

VR is becoming an increasingly popular tool for trade events, as it offers a unique way to showcase products and experiences. Virtual reality can create realistic experiences for customers to feel as if they are using a product. This can be helpful for complex products that are difficult to explain with traditional methods, such as photos or video.

Manufacturers may also utilize virtual reality to better control the context in which their items are seen, ensuring that potential consumers have a pleasant experience. In addition, this immersive technology can create custom experiences for VIP guests, offering them a unique and memorable experience that they are unlikely to forget.

Learn more about how Vection Technologies enables no-code metaverse presentation creation.

Improved Workers’ Safety

Virtual reality has become an important tool in a variety of industries, but it may be especially valuable in manufacturing because improving workers’ safety is always a top priority.

One example of this is factory floors. In these places, there are many potential hazards, from heavy machinery to toxic chemicals. virtual reality can provide workers with a realistic simulation of their work environment, allowing them to rehearse safety procedures and identify potential risks.

Also, by utilizing VR headsets, companies can develop training programs that are specific to each worker’s role. Therefore, workers’ safety is guaranteed.

VR may be used to develop unique training programs that are customized to each employee’s responsibilities. For instance, manufacturers may use virtual reality to ensure that their employees are better equipped to deal with any potential dangers on the job.

Product Development

VR has been a helpful tool in product development, specifically in the manufacturing process. For example, VR allows manufacturers to see how a product will function in the real world and identify potential problems before they occur.

Furthermore, virtual reality may create prototypes of goods and test them for performance and durability while also teaching personnel how to use new equipment or processing techniques. Manufacturers may also use VR to reduce the need for costly and time-consuming trial-and-error methods of product development.

Learn more about real-time design review in VR and the Unreal Engine.

Financial Planning

VR can improve financial planning in several ways. First, VR can simulate different financial scenarios. This can help people to identify potential risks and learn from mistakes that have been made in the past.

Second, virtual reality can create realistic models of factories and other physical assets. This can help businesses to make more informed decisions about where to invest their money and how to allocate their resources.

Credits: <u>Hammer & Tusk</u>

Finally, VR can be used to train employees in financial planning and management. This can help businesses to reduce costs and improve efficiency. VR is a powerful tool that can help businesses to make better financial decisions.

Is VR Here to Stay? Challenges to Overcome

VR has the potential to revolutionize the manufacturing industry, but there are still a few challenges that need to be overcome. First, VR headsets are expensive, and not all manufacturers can afford to invest in the technology.

Second, VR headsets can be bulky and uncomfortable to wear for long periods of time. And finally, VR can be disorienting and dizzying for some people, which can make it difficult to work in a virtual environment.

However, these challenges are not insurmountable. VR headset manufacturers are working on making headsets more affordable, lighter, and comfortable to wear. Therefore, users will become more acclimated to the feeling of dizziness and confusion as VR becomes more popular.

Vection Technologies is helping companies incorporate immersive technologies to foster collaboration and learning and grow sales. Contact us to begin your VR adoption strategy today and start creating value